Product Description

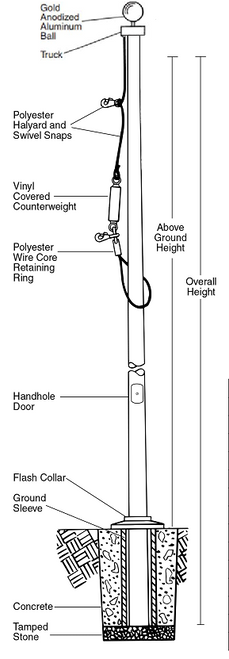

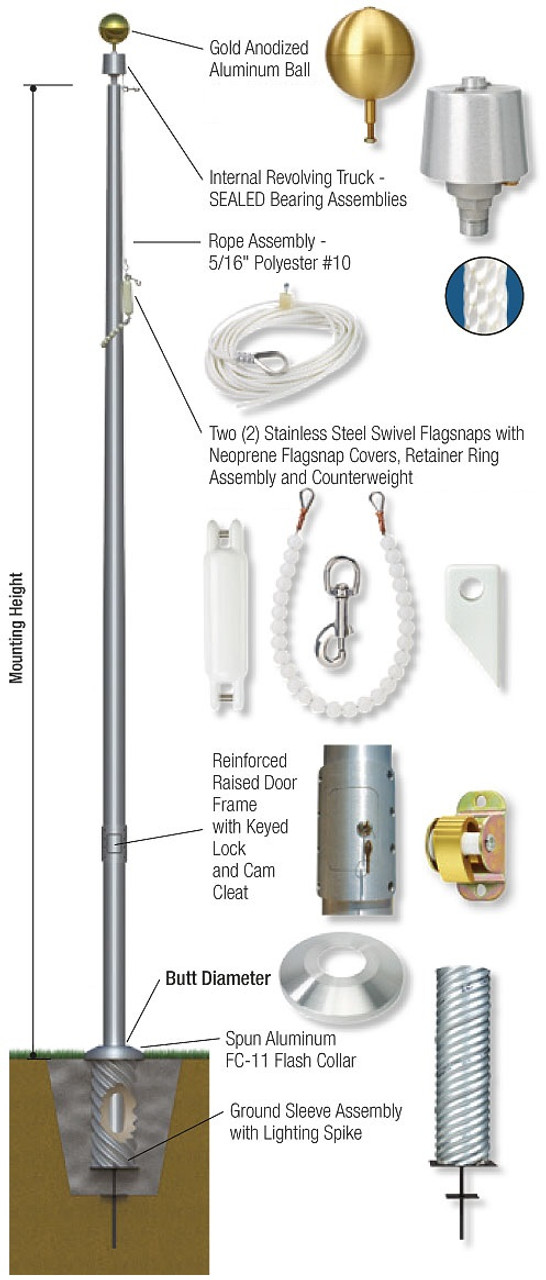

Standard Equipment

- Gold Anodized Aluminum Ball

- Internal Single Revolving Truck (Single Stationary available for Rope ONLY)

- Solid Braid Nylon Halyard (5/16") for Rope-Based / Wire Cable Assembly for Cable-Based

- (2) 3-1/2" Bronze Swivel Snaphooks

- Heavy-Duty Cam Cleat / Stainless Steel Winch Assembly

- Access Door w/ Lock & Keys for Rope-Based / Removable Winch Handle for Cable-Based

- Spun Aluminum Flash Collar

- Corrugated Steel Ground Sleeve or Anchor Bolts for Shoe Base

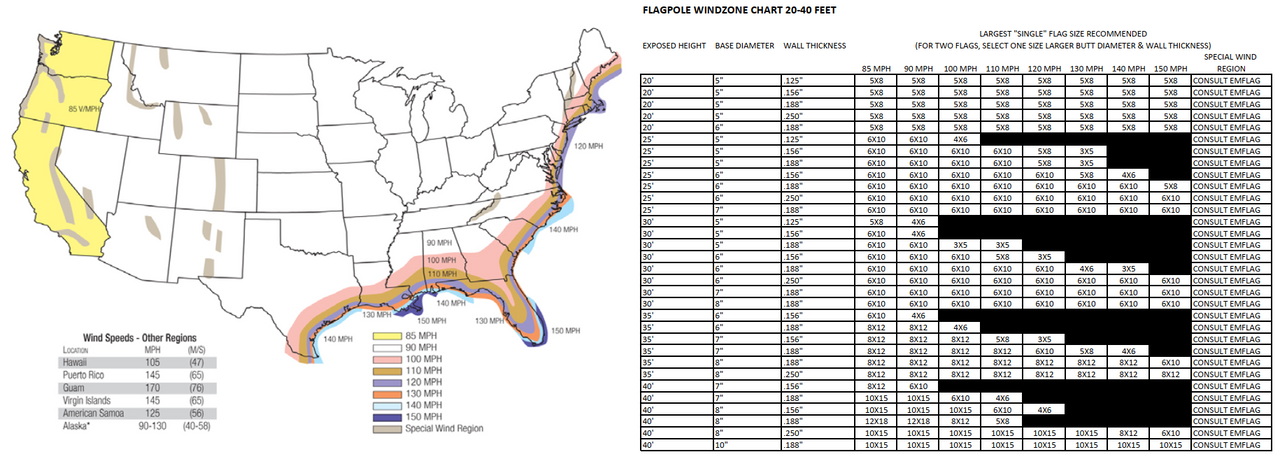

*** SHOE BASE EXCEPTIONS ***

- 30’ must use 6” x .188”

- 35’ must use 7” x .188”

- 40’ must use 8” x .188”

- 45’ must use 10” x .188”

- 50 must use 10” x .188”

- 60 must use 12” x .250”

- 70 must use 12” x .250”

- 80 must use 12” x .375”

(Open Market)

Request Service or Installation Here

|

Rope-Based Flagpoles |

Cable-Based Flagpoles |

|

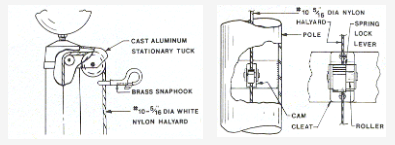

A more cost-effective, vandal-proof internal halyard system. The cam cleat replaces the winch and the door is removable allowing for access to operate the halyard. Standard nylon rope is used in lieu of stainless-steel cable and a stationary truck instead of a revolving truck. This system can be used in 5″ diameter poles and above. The cam system is not recommended on poles 35′ and above. Consult factory for available sizes. This system consists of a nylon rope, which is routed through the interior of the flagpole shaft and is attached to cam cleat mechanism. A flush access door at ground level allows access to the concealed cam cleat. The beaded sling encircling the pole, keeps the flag tight against the flagpole and a neoprene counter weight allows for proper lowering and raising of the flag. The cam system allows for the display of the flag at any position on the pole. This assembly is supplied with a standard stationary truck. An optional revolving truck is available.

|

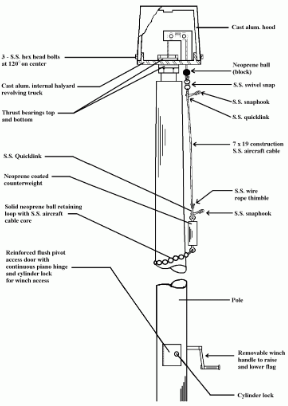

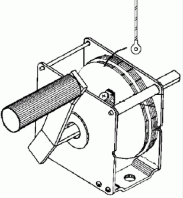

The Internal Winch System consists of a highly flexible stainless-steel cable, which is routed through the interior of the flagpole shaft. The cable is attached to a gearless positive locking winch that allows the display of the flag at any position on the pole. The cable is routed over two pulleys inside the revolving truck and ends with a neoprene ball block to prevent jamming at the poles top. Then, an arrangement, the length of each flag to be flown, is attached. At the bottom of this arrangement a beaded sling encircles the pole and keeps the flag tight against the flagpole. The neoprene-coated counterweight allows for proper lowering of the flag. A removable winch handle is used to raise and lower the flag through an access hole in the pole. A flush-hinged door with a cylinder lock is provided to access and maintain the winch and cable. The winch system is suitable for all poles larger than 5" diameter.

|

|

Standard Equipment

|

Standard Equipment

|

|

|

|

|

Satin Brush – (SAT) A textured mechanical finish produced by abrasive polishing yielding a smooth and uniform appearance. This finish is used on aluminum, stainless steel, and bronze.

|

Clear Anodized Finish – (CLR) Anodizing is a process of electrolysis used on aluminum alloys to increase corrosion resistance and to allow coloring. The common colors are clear, bronze, and black. These finishes are highly recommended in coastal areas and are perfect matches for many building skins. Light bronze, medium bronze and other common colors are also available. (Limited to aluminum)

|

Light Bronze Anodized Finish – (ALB) Anodizing is a process of electrolysis used on aluminum alloys to increase corrosion resistance and to allow coloring. The common colors are clear, bronze, and black. These finishes are highly recommended in coastal areas and are perfect matches for many building skins. Light bronze, medium bronze and other common colors are also available. (Limited to aluminum)

|

|

Medium Bronze Anodized Finish – (AMB) Anodizing is a process of electrolysis used on aluminum alloys to increase corrosion resistance and to allow coloring. The common colors are clear, bronze, and black. These finishes are highly recommended in coastal areas and are perfect matches for many building skins. Light bronze, medium bronze and other common colors are also available. (Limited to aluminum) |

Dark Bronze Anodized Finish – (ADB) Anodizing is a process of electrolysis used on aluminum alloys to increase corrosion resistance and to allow coloring. The common colors are clear, bronze, and black. These finishes are highly recommended in coastal areas and are perfect matches for many building skins. Light bronze, medium bronze and other common colors are also available. (Limited to aluminum)

|

Black Anodized Finish – (BLK) Anodizing is a process of electrolysis used on aluminum alloys to increase corrosion resistance and to allow coloring. The common colors are clear, bronze, and black. These finishes are highly recommended in coastal areas and are perfect matches for many building skins. Light bronze, medium bronze and other common colors are also available. (Limited to aluminum)  |

|

Powder Coat (Painted) Finish – (WHT) Ranging from simple paint to the more complex air-drying epoxies, urethanes, and thermally cured fluorocarbons. These finishes are most commonly used with aluminum and steel. Powder Coating has gained wide acceptance as a low cost, environmentally sound, high quality finish. It is a dry thermally cured painted coating, available in many colors that have excellent durability and abrasion resistance.

|

Powder Coat (Painted) Finish – (BRZ) Ranging from simple paint to the more complex air-drying epoxies, urethanes, and thermally cured fluorocarbons. These finishes are most commonly used with aluminum and steel. Powder Coating has gained wide acceptance as a low cost, environmentally sound, high quality finish. It is a dry thermally cured painted coating, available in many colors that have excellent durability and abrasion resistance.

|

Powder Coat (Painted) Finish – (BLK) Ranging from simple paint to the more complex air-drying epoxies, urethanes, and thermally cured fluorocarbons. These finishes are most commonly used with aluminum and steel. Powder Coating has gained wide acceptance as a low cost, environmentally sound, high quality finish. It is a dry thermally cured painted coating, available in many colors that have excellent durability and abrasion resistance.  |

(IHS-RP - Ground Set) Specification Sheet

(IHS-RP - Ground Set) Specification Sheet