Product Description

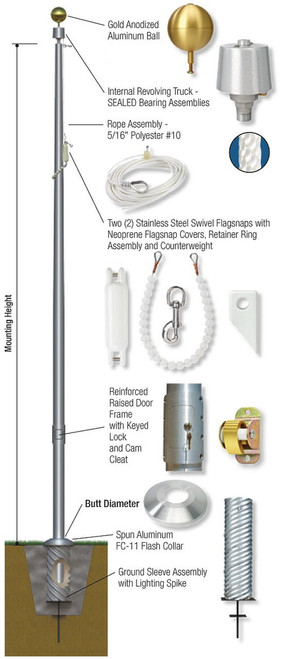

Appearance of Truck may vary, image shown as example

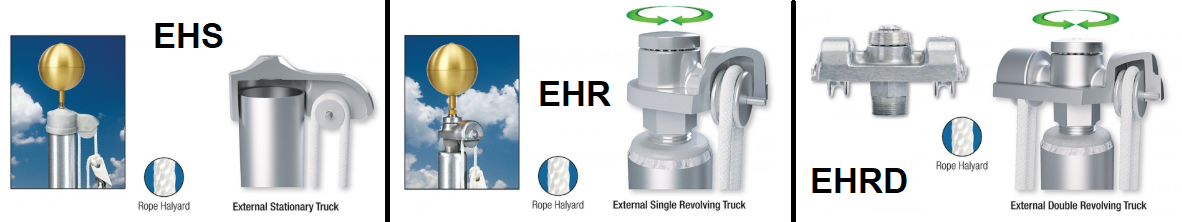

External Halyard Flagpoles consist of the rigging system being located on the outside of the flagpole. A rope runs up the shaft of the flagpole to a truck assembly located at the top, where it passes through a pulley. The rope then returns back down the shaft to be tied off to an external cleat typically located 4 ½’ above grade. External truck assemblies can be stationary or revolving. The revolving truck is available with a single pulley or double pulley. A single revolving external halyard flagpole is the Industry Standard.

Standard Equipment

- Gold Anodized Aluminum Ball

- External Truck (Stationary, Revolving, & Double Revolving)

- Solid Braid Nylon Halyard (5/16")

- (2) 3-1/2" Bronze Swivel Snaphooks

- 9" Cast Aluminum Cleat w/ Stainless Steel Screws

- Spun Aluminum Flash Collar

- Corrugated Steel Ground Sleeve

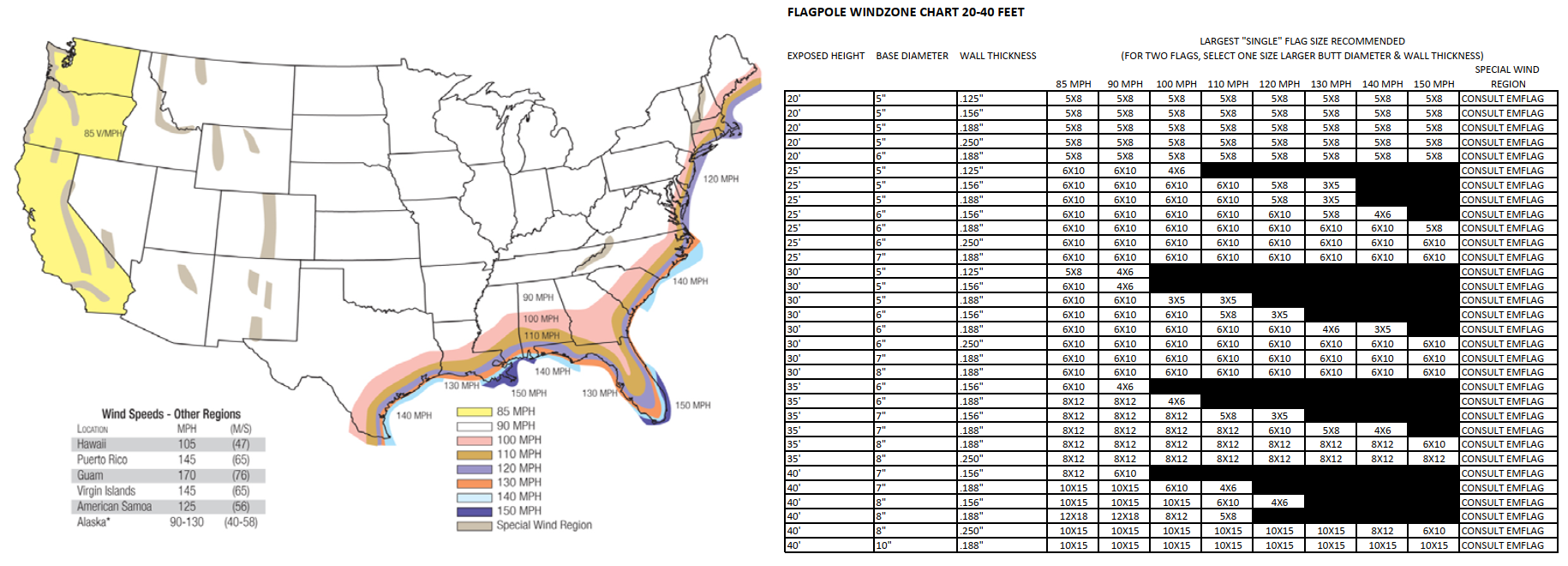

Wind Speed Chart

Specification Sheets

(EHS - Ground Set) Specification Sheet

(EHS - Ground Set) Specification Sheet  (EHS - Shoe Base) Specification Sheet

(EHS - Shoe Base) Specification Sheet  (EHS) Installation Sheet

(EHS) Installation Sheet

(EHR - Ground Set) Specification Sheet

(EHR - Ground Set) Specification Sheet  (EHR - Shoe Base) Specification Sheet

(EHR - Shoe Base) Specification Sheet  (EHR) Installation Sheet

(EHR) Installation Sheet

(EHRD - Ground Set) Specification Sheet

(EHRD - Ground Set) Specification Sheet  (EHRD - Shoe Base) Specification Sheet

(EHRD - Shoe Base) Specification Sheet  (EHRD) Installation Sheet

(EHRD) Installation Sheet

Request Service or Installation Here

Note:

- The truck's appearance may vary from the image shown.

- Anodizing is an electro-chemical process resulting in a hard inert aluminum oxide layer on the flagpole surface. Due to the tapering process and geometry of the flagpoles there is always a chance of slight color variation along the pole surface. Bronze anodized flagpoles, especially light and medium bronze have more pronounced color variations. If a bronze anodized finish is required, to minimize color variation we recommend dark bronze anodizing. If a light or medium bronze anodized finish must be supplied, we will adjust our price accordingly, but we cannot guarantee a uniform color throughout the pole surface.

(Open Market)

|

Satin Brush – (SBW) A textured mechanical finish produced by abrasive polishing yielding a smooth and uniform appearance. This finish is used on aluminum, stainless steel, and bronze.

|

Clear Anodized Finish – (CLR) Anodizing is a process of electrolysis used on aluminum alloys to increase corrosion resistance and to allow coloring. The common colors are clear, bronze, and black. These finishes are highly recommended in coastal areas and are perfect matches for many building skins. Light bronze, medium bronze and other common colors are also available. (Limited to aluminum)

|

Light Bronze Anodized Finish – (LBA) Anodizing is a process of electrolysis used on aluminum alloys to increase corrosion resistance and to allow coloring. The common colors are clear, bronze, and black. These finishes are highly recommended in coastal areas and are perfect matches for many building skins. Light bronze, medium bronze and other common colors are also available. (Limited to aluminum)

|

|

Medium Bronze Anodized Finish – (MBA) Anodizing is a process of electrolysis used on aluminum alloys to increase corrosion resistance and to allow coloring. The common colors are clear, bronze, and black. These finishes are highly recommended in coastal areas and are perfect matches for many building skins. Light bronze, medium bronze and other common colors are also available. (Limited to aluminum) |

Dark Bronze Anodized Finish – (DBA) Anodizing is a process of electrolysis used on aluminum alloys to increase corrosion resistance and to allow coloring. The common colors are clear, bronze, and black. These finishes are highly recommended in coastal areas and are perfect matches for many building skins. Light bronze, medium bronze and other common colors are also available. (Limited to aluminum)

|

Black Anodized Finish – (BLA) Anodizing is a process of electrolysis used on aluminum alloys to increase corrosion resistance and to allow coloring. The common colors are clear, bronze, and black. These finishes are highly recommended in coastal areas and are perfect matches for many building skins. Light bronze, medium bronze and other common colors are also available. (Limited to aluminum)  |

|

Powder Coat (Painted) Finish – (WHT) Ranging from simple paint to the more complex air-drying epoxies, urethanes, and thermally cured fluorocarbons. These finishes are most commonly used with aluminum and steel. Powder Coating has gained wide acceptance as a low cost, environmentally sound, high quality finish. It is a dry thermally cured painted coating, available in many colors that have excellent durability and abrasion resistance.

|

Powder Coat (Painted) Finish – (BRZ) Ranging from simple paint to the more complex air-drying epoxies, urethanes, and thermally cured fluorocarbons. These finishes are most commonly used with aluminum and steel. Powder Coating has gained wide acceptance as a low cost, environmentally sound, high quality finish. It is a dry thermally cured painted coating, available in many colors that have excellent durability and abrasion resistance.

|

Powder Coat (Painted) Finish – (BLK) Ranging from simple paint to the more complex air-drying epoxies, urethanes, and thermally cured fluorocarbons. These finishes are most commonly used with aluminum and steel. Powder Coating has gained wide acceptance as a low cost, environmentally sound, high quality finish. It is a dry thermally cured painted coating, available in many colors that have excellent durability and abrasion resistance.  |